Developing the gold-standard for automated bone prep and milling

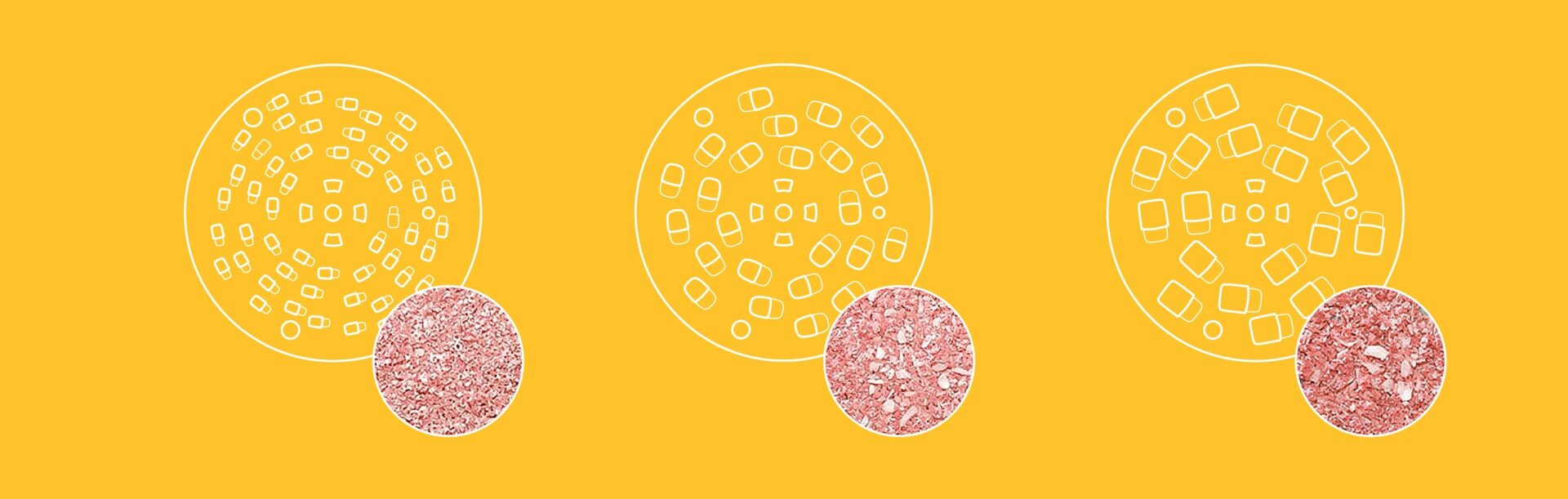

Spinal fusion surgery often requires that bone be harvested from the patient, reduced to a small and consistent size, and reintroduced into the patient to promote bone growth. Several years ago, Stryker identified an opportunity to replace this painstaking, manual process with an efficient powered solution – the Bone Mill. After the Bone Mill made them a market leader, Stryker sought to redesign the power base and mill, and develop a new disposable that enables automated tissue removal prior to milling. The resulting Bone Mill+ provides more advantages than ever before.