Article

The Custom vs. COTS Conundrum: Which Part Is Best for Your Next Product?

Discover the pros and cons of using custom or COTS parts in your new product along with how each will affect your development roadmap and business goals.

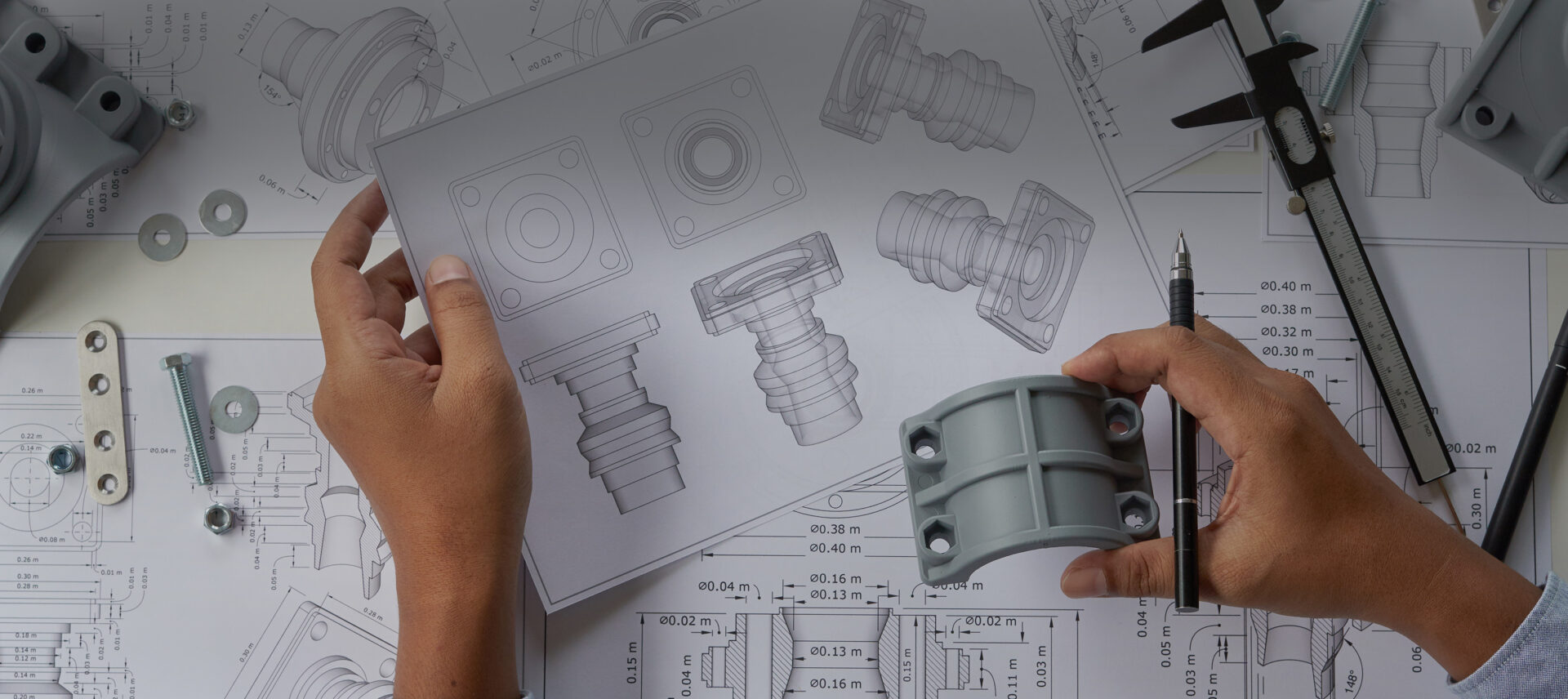

The need to make wise decisions about your product’s development is an intrinsic part of the process. And as a technical leader, one question you commonly face is how to source the components for your future product. Is it better to use commercial off-the-shelf (COTS) parts and modify your product’s design to accommodate them? Or is it best to create something custom that’s specifically tailored to and optimized for the design?

As with most things in product development, there’s no one-size-fits-all answer. True, there are some obvious times when one option is the clear choice over the other. But in most cases, you’ll need to weigh your competing demands — cost, development schedule, IP protection, team capabilities, and more — against the pros and cons of each option available.

Here’s what to consider each time you face this particular question.

Signs You Need a Custom Part for Your Product

Sometimes there’s simply no alternative to designing a custom part. You can be confident that a custom solution is the best path forward if:

- There’s no off-the-shelf part available for what you’re trying to accomplish

- A COTS option does exist, but there’s no way to integrate it into your design (for example, it’s too big, too small, or too complicated to interface with the rest of the product)

- Incorporating a COTS option would require you to ignore one or more of your success drivers

- The part would detract from your organization’s brand identity and/or design language

Any time a COTS part would impact the integrity or functionality of your solution, it’s time to consider custom.

Reasons to Go with a COTS Part

On the other hand, there are plenty of times when reaching for a COTS part is the right choice. And frankly, at times it would be stupid to go through the hassle of designing a custom component. Don’t hesitate to consider using an off-the-shelf solution for needs like:

- “Jellybean” circuit board components

- Standard hardware such as screws and fasteners

- Connectors and basic power sources (like AA batteries)

- Anything that isn’t part of your product’s “special sauce” or unique value proposition

Don’t reinvent the wheel if a COTS part will easily do the trick — even if you think the part would be cheaper if you create your own version. For example, if you’re looking for ways to stretch your development budget, you might look at a connector and think, “How hard could it be to create a cheaper version of our own?”

It’s much harder than you might imagine.

Many of these standard-issue products have taken years for suppliers to perfect. In most cases, your engineers won’t be able to replicate a decade’s worth of learning in a month or two — nor is it the best use of their time and energy (or your budget) to try.

How to Make a Decision About Your Product’s Components When the Choice Isn’t Clear

Of course, most of the time making the decision about which path to take is more gray and murky than black and white. And to arrive at the best possible course of action, you’ll need to weigh a number of factors and demands.

Spinning up a good, old-fashioned pros and cons list is always a helpful exercise. To get you started, here are some of the pluses and minuses we’ve experienced when choosing between custom and COTS parts.

The Pros and Cons of a Custom Part Solution

The most common reason to opt for a custom-fit solution is that you can create the exact part you need. It fits like a glove, blends with your existing design language, and won’t require any jerry-rigging or workarounds to get it to function.

Additional pros:

- You can maintain control over the design and its manufacturing (which can make it easier to comply with safety and regulatory requirements). Say you need a circuit card. Going custom allows you to design the right logic, select the parts that go on it, and control how it is eventually manufactured and assembled.

- You’re not at the mercy of a supplier who can change the part design at any time as they see fit. Any change the supplier makes could have unintended impact to your product’s consistency and efficacy.

- The IP is yours — no need to worry about patent infringement or competitors benefitting from your design.

- Your BOM (build of materials) cost could be lower, especially if the alternative COTS solution contains additional components you could get rid of.

The biggest con of developing a custom solution is that it requires significant technical expertise and bandwidth to build. Some teams just aren’t equipped. Beyond that, there are other drawbacks to keep in mind:

- Your R&D cost for developing a custom-fit solution can be significant. In general, the more complex the problem, the more expensive creating a custom solution will be.

- The ins and outs of manufacturing your part will fall on you to figure out. This includes everything from the initial capital investment to testing to ongoing production.

- It takes more time to develop a custom solution, which could negatively impact your product’s time to market, cause you to miss your market window, and hinder your ability to beat the competition.

If you find that you truly do need a custom part, but your team doesn’t have the bandwidth or capability to manage all this, you can engage a product development firm that does. But you’ll need to be realistic about your needs at the outset and build the cost of a third-party engagement into your product development plan.

Consider the Pros and Cons of Off-the-Shelf Parts

In many ways, the pluses and minuses of choosing a COTS part are simply the opposite of the pros and cons of going custom. However, it’s worth stating that with an off-the-shelf solution:

- There’s rarely any initial investment required — the price tag you see is generally what you’ll pay.

- Assuming the part is readily available, the lead time to source it is predictable and much faster than designing your own item.

- The component itself has already been tested and validated.

Still, there are challenges to keep in mind. If you select a COTS part, you’ll:

- Lose control over the part’s design and manufacturing process.

- Need to navigate a potentially complex IP landscape to make sure you’re not infringing on any protected material.

- Potentially pay more for BOM costs, especially if you have to add additional components to make it work.

- Need to consider the part’s end of life. What happens if the part becomes obsolete before your product does? Will you have to rethink your entire design or order and store large quantities of inventory so you don’t run out?

It’s also common for COTS parts to add more capability to the product than the design truly calls for, which can further add to the cost involved. For instance, if you need touchscreen capability, you might think adding tablet computer would be a good solution. But in reality, you’d end up paying for complex, expensive features you don’t need.

Balance All the Pros and Cons Against Your Overarching Business Needs

As you’re nearing a final decision, take everything you’ve thought about to this point and weigh it all against the business goals you’re trying to achieve. Whichever avenue you ultimately choose must align with your strategic plans.

Consider:

- Your success drivers. In other words, what must your product design achieve in order for this product to be successful?

- Specific market windows or launch dates you need to hit. If a custom part will prevent you from meeting a non-negotiable deadline, you’ll need to figure out a COTS option (or adjust your design).

- Your product volume. It’s only worth investing in a custom solution if the volume you plan to produce makes it economically feasible.

- Supply chain challenges. If you’re considering an off-the-shelf part that’s manufactured in a country affected by war, a reputation for misusing IP, or trade embargoes, it might be better to look elsewhere or design your own solution.

- Budget. If you simply don’t have the money to spend on a custom component, make that clear from the get-go so your product development team can generate concepts that will work within your financial constraints.

- Intellectual property goals. Will a custom solution contribute to your company’s IP landscape? That’s a good reason to put COTS options aside.

Be sure to also weigh the opportunity cost inherent in each potential path. What tradeoffs or sacrifices are you making that could cost you down the road?

Make Decisions About Your Product With the Long View in Mind

When it comes to choosing between custom or off-the-shelf parts, there’s often more than one acceptable approach. Therefore, the deciding factor might be this: Which choice will best support your business’s long-term product development roadmap?

If the off-the-shelf part you’re considering meets your needs — and if you’re fairly certain it will be available for years to come and won’t be modified — you’re probably safe in selecting the ready-made option. But if your COTS solution requires customization to make it fit — or if there are supply chain issues that could make it impossible to source it in the future — you should consider going custom.

No matter which path is best, you don’t have to walk it alone. A good product development partner like M3 can help you make smart decisions about your product from the concept phase all the way to development and beyond.